Assessment &

Analysis

- Identify the problem

- Determine the suitability of orthotic

intervention to address the problem

- Define the objectives of orthotic

intervention

- Determine the orthotic design and

suitable orthotic materials

Points to consider:

- Condition of the skin with attention

to: fragile skin, circulation, wounds,

etc.

- Sensation

- Bony prominences

- Pain

Choosing correct

thermoplastic

Points to consider:

- Localization

- Age of the patient

- Constitutional type

- Pathology

| |

Kids |

Teens |

Adults |

| Body

part |

|

|

|

| Finger |

Multicast Standard

0.8mm Micro |

Multicast Standard

0.8mm Micro |

Multicast Standard

1.6mm Micro |

| Wrist |

Multicast Standard

1.6 – 2mm Micro |

Multicast Standard

2 – 2.5mm Micro/Mini |

Multicast Standard

2.5 – 3.2mm Mini |

| Elbow |

Multicast Rigid

2mm Micro |

Multicast Rigid

3mm Mini

|

Multicast Rigid

3.2mm Non/Mini |

| Shoulder |

Multicast Standard

2mm Micro |

Multicast Standard

2.5mm Mini/Multi |

Multicast Standard

3mm Non/Mini |

| Body |

Multicast Rigid

3mm Multi |

Multicast Rigid

3mm Multi |

Multicast Rigid

4mm Mini |

| Lower

leg |

Multicast Standard

2mm Micro |

Multicast Rigid

3.2mm Mini/Non |

Multicast Rigid

3.2mm Mini/Non |

Multicast

Standard can be substituted

by Multicast

Ortho depending on processing

and splint preference, e.g. Multicast

Ortho is transparent when heated

Material selection

- Points to consider:

- Multicast Standard is preferable for the orthosis with

the small surface.

- Multicast Standard is preferable for children.

- Multicast Standard is preferable when applied over a bandage.

Material does not stick to bandage.

Highly recommended for post-operative

splinting and burn injuries.

- Multicast Rigid is

preferable for orthosis with large surface.

- Choose a thermoplastic with large

ventilation holes, such as Micro and

Multi to prevent skin maceration.

- If have limited experience with splinting

techniques choose Mini perforated plates

instead of Multi.

- Non-perforated plates are only used

for non-circular orthosis that cover

less then half of the body surface.

Absence of ventilation holes will lead

to skin maceration.

- Choose Multicast Standard or Multicast Ortho when using Gravity-Assisted Moulding

techniques.

- For vertical moulding choose thermoplastics

with good adhering surface, such as Multicast Ortho or Multicast Rigid.

Producing

the custom pattern

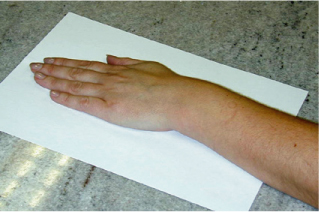

1. Position the client’s hand and forearm

in pronation on the paper towel.

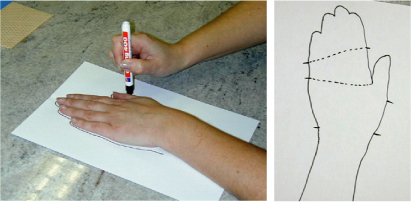

2. Trace around client’s

hand and forearm and note landmarks.

3. Add guide marks to the

pattern.

4. Connect the guide marks

to create the custom pattern outline.

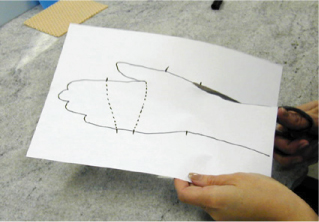

5. Cut out the paper pattern.

6. To check the fit, apply

pattern to the client’s limb and position

the joints as they will be when orthosis

is moulded. Transfer the pattern on the

thermoplastic. Size and cut.

Protecting bony

prominences

- Flare or dome material away from the

bony prominence during the moulding

process.

- Pad the bony prominence(s) before

molding thermoplastic. Don't add padding

after moulding because it will compress

the tissue over the bony prominence.

Skin problems?

Any kind of thermoplastic material worn

permanently by the patient over a long

period will suffocate the skin. The material

does not breathe and as such does not

drain away transpiration and exudation.

After some time, epidermis will result.

To prevent skin problems:

- Use Micro or Multi perforated sheets.

Mini perforated sheets do not improve

ventilation: the perforation will only

result in local ventilation, near the

holes.

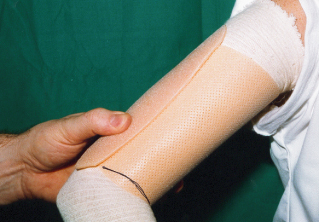

- Apply stockinet under the thermoplastic

(e.g. braces of tibia, humorous, corsets).

- Line the splints with felt or self-adhesive

toweling cloth. This improves comfort

as far as softness and absorption of

transpiration are concerned. Before

lining a splint with felt, the space

occupied by the felt should be taken

into account. This can be avoided by

attaching felt to the limb or by using

a thick stockinet.

- Provide a splint with the larger ventilation

holes.

- Remove the splint or brace for some

time every day (if possible).

Processing Methods

Water Bath - also available from Algeos

The material may be heated in the following

ways:

- Water (from 60 - 75°C)

- Steam (from 90°C)

- Dry heat (max 150°C)

- Heat gun

- Heating plate

Multicast Standard Processing:

The material can be processed after 2

minutes of heating at 75°C (167°F)

or 1 minute of heating at 80°C or

until a dark “glazy” discoloration has

appeared.

After heating in water at 75°C (167°F)

lift the material out and place it immediately

on a dry towel. Fold half of the towel

over the whole plate to dab excess moisture.

Material can be now placed

directly on the bare skin. In the meantime,

the temperature has fallen to about 40°C/105°F,

which is experienced as agreeable. If

working at a higher temperature is required

in order to get more modeling time it

is advisable to protect the skin with

stockinet or another kind of tubular bandage.

Multicast Ortho

& Multicast Rigid Processing:

Using a water bath processing

temperature is between 60°C-65°C.

With an oven: 100°C.

To soften Multicast Ortho

or Rigid, place the material into a water

bath at temperature 60°C - 65°C

(140°F - 159°F) for 60-90 seconds

or until sufficiently soft.

When ready, take the

material out of the water and place on

a flat surface (preferably a wooden board)

for 10 seconds. Temperature will immediately

drop to 35°C (95°F).

Take the splint with wet hands and position

it onto the patient. Immediately afterwards

wet your hands with cold water. This will

speed surface hardening and help prevent

imprints

Adjustment &

Trimming

While material is still somewhat warm,

use 3-point pressure to flare away from

the bony prominences. Correct the gaping

trough by squeezing in the sides of the

orthosis.

Mark the trip line (with

a fingernail or pen). Trim lines to ensure

freedom of the joints.

Spot heat the distal

edge by submersion in a hot water. Fold

the edges as necessary. Reheat and re-cut

the edge with long, smooth strokes to

remove irregularities.

Grind the edges (after cooling!)

and cover the edges if preferred.

When attaching straps, follow

these steps:

- Determine the optimum location and

width of the straps.

- Dry heat the adhesive backing of

the hook patch with a heat gun.

- Dry heat the attachment site on the

orthosis.

- Embed one edge of the patch into preheated

material.

- Remove the paper backing from the

hook and fold over one edge of the patch.

|